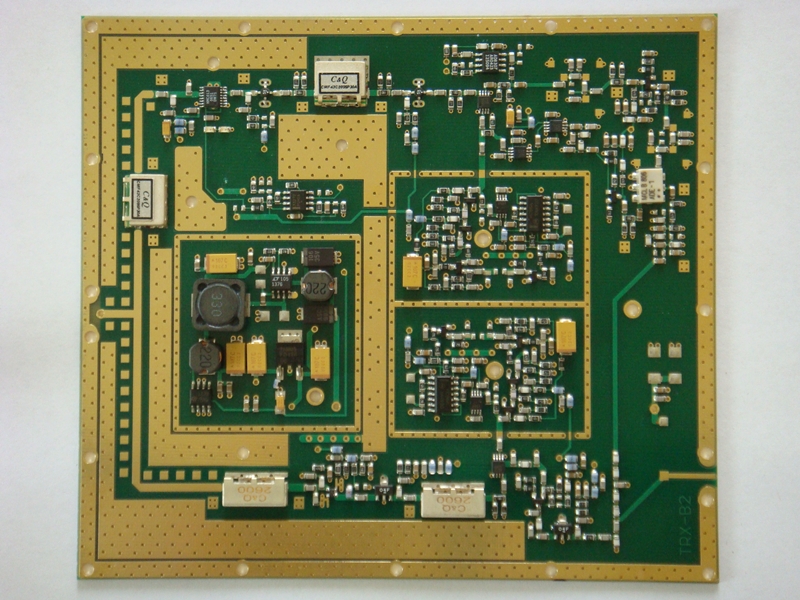

Three-layer-PCBS

Three-layer PCBs:

- basic core material: FR4, thickness 1/1.5mm, 18/18 µm copper

- Third layer printed: as polymer CU cream copper, galvanically strenghtened to 10 µm.

- Third layer laminated: CU-foil 18/or 35/µm laminated on a two-layer core 1 mm thick.

- To prevent a bow-effect, the pcb is produced actually as a 4-layer board

- drilled according to the drilling data, drilled holes metallized

- solder mask photolithographically placed

- service print

- galvanic tin

- tinned with Cn100C solder /not recommended/ or

- treated by OSP or

- galvanic gold over galvanic nickel

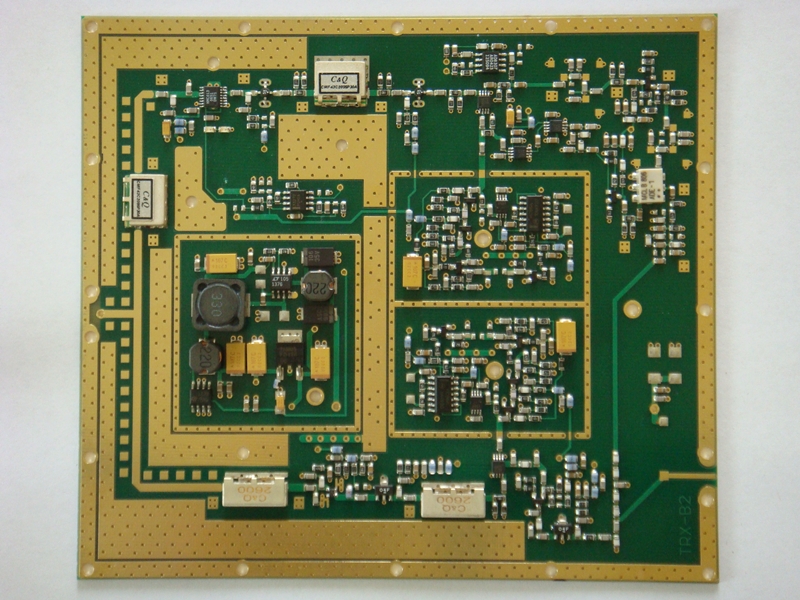

Maximum size:

- 250 x 300mm when galvanic tinned

- 250 x 300mm when HAL tinned /solder mask needed

- 250 x 300mm OSP

- 250 x 300mm galvanic gold

Needed documents:

- GERBER data with check prints or

- positive films of tracks, solder masks and service print. Set of data files allways required for production purposes.

- EXCELLON drill data

- The boards are milled to final dimension only. Others must be consulted during placing the order.

|